At this year’s LOUNGES 2023 in Karlsruhe, we presented our joint automation simulation solution with our partner gat for the first time. True to the motto “Automation meets IT”, our solution connects the planning world with the real world and thus supports the entire life cycle of a plant in a transparent and uniform process.

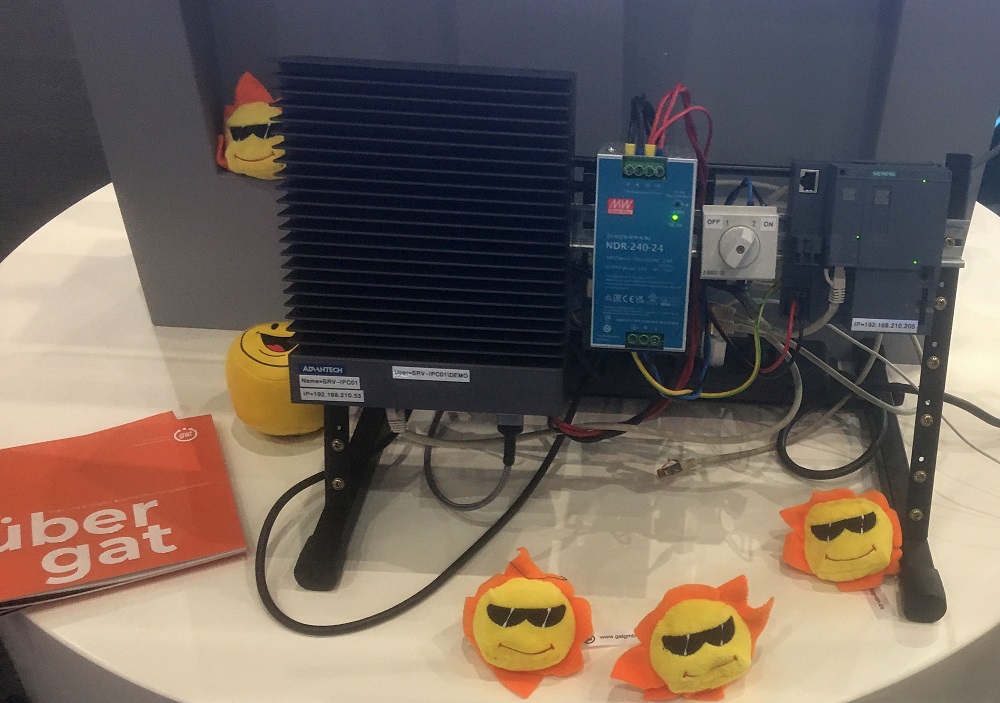

Our visitors had the opportunity to experience our solution in a way that was realistically identical to how it would work in the customer’s environment, as we had set it up completely with an industrial PC, programmable logic controller (PLC) and the corresponding OPC-UA communication between simulation and control.

Our software was seen as extremely useful by potential customers, as it can model and simulate a wide range of piping systems and their various components. Taps can be easily added or removed and flow rates, pressure drops and pump capacities can be calculated to support the system’s entire lifecycle, from design to construction and operation.

What was particularly exciting for our visitors was that our solution can be connected to the real world of automation. The real data such as flow rates, tank levels and valve states can be queried through the dynamic simulation, which can be connected to the real automation of the storage and distribution systems via OPC UA. This enables simulation and prediction of operations based on real data. The collection of real data over time enables continuous improvement of the prediction. The fact that our solution can provide intelligent tap management and an early warning system for critical situations was seen by our visitors as valuable support in their daily work.

The ability to simulate new production cycles in advance to identify potential bottlenecks and to optimise costs in the design and construction of tank and piping systems, as well as the generator system, attracted a great deal of interest.

Overall, participation at the show was promising. Visitors’ reactions to our automation simulation solution were very positive, especially as it can be used for other customer requirements in addition to those already presented.

In addition to modelling, simulation and operational monitoring and control, our solution will also support mass balancing, predictive maintenance and documentation of existing plants. In this way, different topics can be addressed within one solution in a cost-saving manner.

We look forward to further developing our solution and helping customers in the pharmaceutical and chemical industries to optimise their business processes.

Read more about our solution

Find out more about the event